Category

a to Z Full Automatic Turnkey 330ml 500ml 1500ml Pet Plastic Bottle Drinking Mineral Pure Water Filling Plant Price Liquid Beverage Bottling Filling Machine

Mineral water filling machine Monoblock means the filling machine integrates washing machine, filling machine and cappin

Basic Info

| Model NO. | CGF24-24-8 |

| After-sales Service | Online Support |

| Warranty | 1 Year |

| Type | Gravity Filling, Volumetric Filling Machine |

| Automatic Grade | Automatic |

| Material Type | Liquid |

| Filling Valve Head | Multi-Head |

| Feed Cylinder Structure | Single-Room Feeding |

| Dosing Device | Capacity Cup |

| Filling Principle | Atmospheric Pressure |

| Packaging Container Lifting Structure | Chute Lifting |

| Structure | Rotary |

| Packaging | Bottle |

| Packaging Material | Plastic |

| Category | Filling Machine |

| Capacity | 10000-12000bph |

| Bottle Materia | Pet |

| Cap Category | Screw Cap |

| Key Materia | SUS304 |

| Inspection | in House, ISO 9001-2000, Ce |

| Transport Package | Wood Case |

| Specification | 3000*2250* 2220 Mm |

| Trademark | NCR |

| Origin | Jiangsu, China (Mainland) |

| HS Code | 8422301090 |

| Production Capacity | 30 Set/Sets / Month |

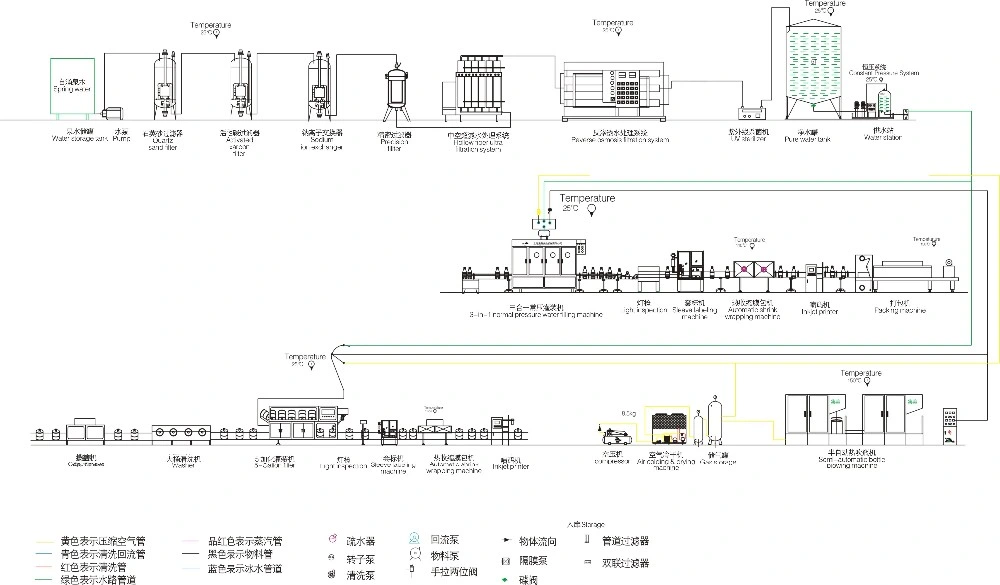

Product Description

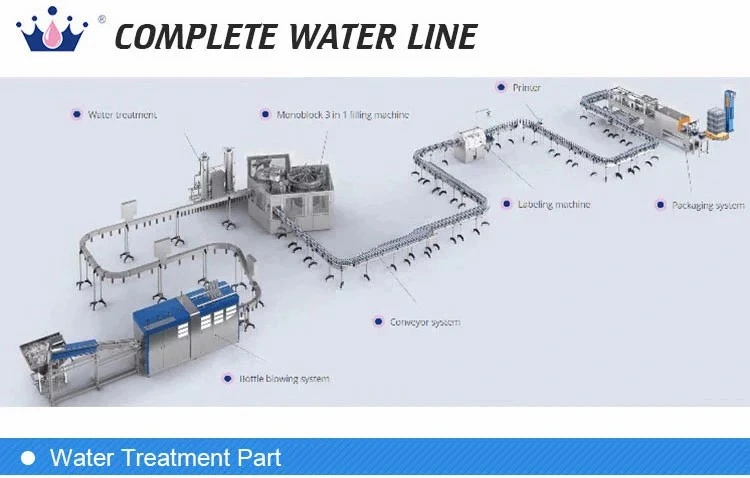

Mineral water filling machine

Monoblock means the filling machine integrates washing machine, filling machine and capping machine in one frame. The driving system will be transmitted step by step which makes the speed more stable.The monoblock filling machine will be made basing on:1, the production capacity per hour2, bottle type: plastic bottle, glass bottle or another3, cap type: plastic screw cap, aluminum screw cap or another

| Mineral water filling machine | ||||

| Model | CGF12-12-4 | CGF18-18-6 | CGF24-24-8 | CGF32-32-10 |

| Capacity | 3000-4000BPH | 5000-6000BPH | 8000-10000BPH | 10000-14000BPH |

| Applicable bottle | Plastic bottle 500ml-1.5L Plastic screw cap | |||

| Applicable filling content | Mineral water, wine, non-carbonated water | |||

| Washing station | 12 | 18 | 24 | 32 |

| Filling nozzle | 12 | 18 | 24 | 32 |

| Capping head | 4 | 6 | 8 | 10 |

| Main motor power | 2.2kw | 2.5kw | ||

| Water pump power | 0.37kw | |||

| Dimension (mm) | 2350*1850*2450 | 2700*2100*2450 | 2800*2400*2450 | 3200*2800*2450 |

| Weight (kg) | 3500 | 4500 | 5500 | 6800 |

Main Features1. Machine structure 1) washing, filling and capping part in one unit;

2) one driving system makes the speed more stable

3) need one person to operate the machine

4) no noisy while running

5) more compact

6)different bottles can be applied in same machine (the bottle neck should be the same)

2. Washing part 1) the star wheel to hold the bottle neck to avoid damage the bottle mouth

2) there is nylon grip to protect bottle mouth

3. Filling part 1) round liquid tank, no residual after filling

2) the valves are stainless steel 304

3)no bottle no filling

4)filling level can be adjusted

4. Capping part 1) there is anti-rotary blade to fix the bottle without moving

2) the capping torque can be adjusted

5. Control system 1) PLC control

2) Touch screen

6. Electric part -- All the electric parts are well-known brand.

Please send us the inquiry with above points so that we can help to send better quotation for reference.

1) the liquid tank is round, there is no residual after filling

2)the material is SUS304 which is anti-corrosive

3) different bottles can be used in same machine (the bottle neck should be the same) by changing some parts;

4) Less area to place the machine

5)Low cost in investment

6) Low energy consumption