Category

Customized Injection Mold for Car Backseat Headrest Hanger

Customized injection mold for Car Backseat Headrest Hanger EQUIPMENT LISTSample show Production processing Company Profi

Basic Info

| Shaping Mode | Injection Mould |

| Surface Finish Process | Electroplating |

| Mould Cavity | Multi Cavity |

| Plastic Material | ABS |

| Process Combination Type | Single-Process Mode |

| Application | Car, Household Appliances, Furniture, Home Use |

| Runner | Cold Runner |

| Design Software | AutoCAD |

| Installation | Fixed |

| Certification | ISO |

| Standard | HASCO |

| Customized | Customized |

| Transport Package | Free-Fumigation Three-Plywood Case |

| Specification | customized |

| Trademark | GV |

| Origin | Guangdong, China |

| HS Code | 84807100 |

| Production Capacity | 500sets Per Year |

Product Description

Customized injection mold for Car Backseat Headrest Hanger

| Mold Description | |

| Mold Standard | DME or HASCO |

| Mold Base | LKM,DME,HASCO,FUTABA |

| Cavity /Core steel | H13,S-7,S136,SS420,NAK80,P20 and other material as requirement |

| Hot Runner | Yudo |

| Cavity | Multi or single cavity |

| Gate type | Side gate,Sub gate,Pin point gate,Edge gate etc |

| Hydraulic cylinder | PARKER, TAIYO, STAUBU, JUFAN |

| Mold components | DME, Progressive, PCS, Punch, Royal, etc |

| Steel Treatment | Heat Treatment, Nitriding, Chrome Plating |

| Surface finish | SPI standard, VDI EDM, Texture, etc |

| Texture | Mold-tech, Yick Sang, Ni Hong ,Tanazawa etc |

| Plastic Material | PP, PC, ABS, PE, HDPE, PET, POM, PMMA, PA(GF), PBT(GF), PVC, PPS,etc |

| Product weight | 5.0g~15kgs |

| Mould Life | 0.3 Million Shots- 1Million shots |

| Delivery Time | 4Weeks T1 samples , exact time depends on Mould Complexity |

| Packaging | Free-Fumigation Three-Plywood case for moulds, cartons for parts |

| Design software | CAD,UG, Pro E, Solidworks |

| Value-added service | Dust-free Spraying, Silk-screen Printing, Ultrasonic Welding, Thermal Bonding, Assembling, Prototype |

| Service area | Transparent, Over mold, double color, air assistant forming, deep barrel, Design R&D, Assembly |

| Our Capability | Auto, Aerospace, Household, Electrical, Industrial, Medial, Toys, Office, Cosmetic, Outdoor, OA Equipment etc |

Production processing

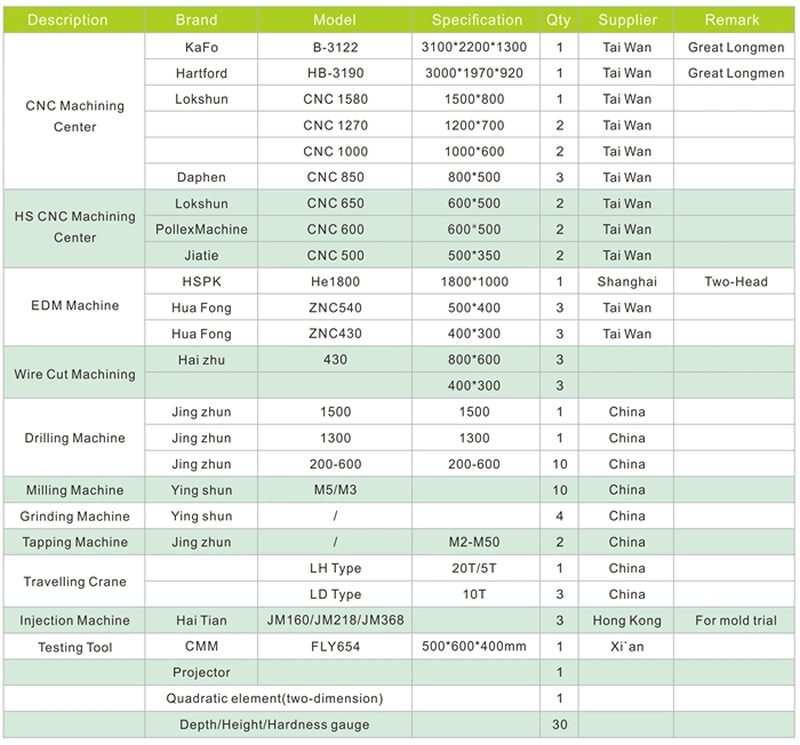

Company ProfileGreen Vitality Industry was established in July, 1993 engaged in CNC processing in Shenzhen.The first mold factory was found in Shenzhen in 2000. In 2007, Green Vitality was registered in Hong Kong, and set up an overseas branch office in Shenzhen for export trade.In 2013, our factory merged with another factory and moved to Dongguang City.With constant growing, in 2018 we built a new wholly-owned factory, named Kidyson Mold in Shajing, Shenzhen.Today, with rich mold experience and a steady engineering and manufacturing team, Green Vitality has become a reliable supplier as well as the strategic partner of customers worldwide to provide the most efficient solution for their application.In the future, we will continue to provide value-added and one-stop service, introduce new advanced technology and machines, expand our injection mold and molding envelope.Facilities"High Precision, High Quality, Effective, Optimum Cost & High Level Service" is our development route towards each project. We attach great importance to tracking and appliance of high-tech home and abroad. In mould technology, advanced hot runner mould flow analysis and optimum mould construction technique is adopted.Our company is also equipped with high-precise machining and three-coordinate inspecting equipments such as high speed CNC machining center, high speed extra large CNC milling, and deep hole drilling machine, etc. We also adopt first-class CAD/CAM technology in designing which enables us develop and manufacture large-volume, complicated, deep-cavity, thin-wall, and precise moulds.We're specialized in manufacturing various kinds of medium and large injection moulds for automotive parts, houseware and industrial parts, etc. 90% of our moulds are exported to more than 30 countries such as Europe, North America, South America, Mid-east and Asia.ASSEMBLY & SECONDARY OPERATIONSGreen Vitality Industry packages, assembles and performs secondary operations to help shorten the supply chain, provide turnkey manufacturing, and reduce lead times and overall cost.In-cycle assembly and in-house assembly lines available to shorten supply chain.Decorating and packaging options are also available to make Green Vitality Mold a one-stop shop solution.SECONDARY CAPABILITIESUltrasonic WeldingDesco Centrifugal DryerMilling and LathingWire Dressing and AssemblySonic WeldingHeat StakingHot StampingPad PrintingVacuum MetalizingSilk ScreeningPaintingAdvantagesWe provide value-added and one-stop service, from plastic injection mold design to delivery.We also provide out-source service of dustless auto painting, electroplating, silkscreen to partner factory. Our advantages:Manufacturing and exporting experience for over 25 years. ISO 9001:2015 approved.Products are supplied to over 50 countries.One-stop service for aluminum profiles, plastic parts, rubber parts, and moulds. Save time and save money for you.In-house mold design and building capabilities.No reclaimed material used to ensure high quality. Keep secret to your idea and your design.Professional design team, mold maker engineer. OEM/ODM service.Professional QC and R&D teams to assure high quality.Professional sales team. Good English capabilities and communication skills.No MOQ and Prompt delivery. For prototype: 3-7 days. Production orders can be arranged specially to meet customer's urgent demands.Geographical advantages: within one hour to airport or sea port, near to Hongkong.