Category

Plastic Crash Helmet Injection Mould

Plastic Crash Helmet Injection Mould: 1. High quality material 3. Hot Runner: DME/LKM/HASCO 4. Mould Life: 500, 000~1, 2

Basic Info

| Shaping Mode | Injection Mould |

| Surface Finish Process | Polishing |

| Mould Cavity | Single/Multy |

| Plastic Material | PP, PC, PS, PE, PU, PVC, ABS, PMMA Ect |

| Process Combination Type | Progressive Die |

| Application | Car, Commodity, Home Use |

| Runner | Cold Runner |

| Design Software | UG |

| Installation | Fixed |

| Standard | HASCO |

| Customized | Customized |

| Mould Material | 45#, 50#, P20, H13, 718, 2738, Nak80, S136, SKD61 |

| Deliery | by Sea |

| Design Day | 3 Days |

| Delivery Time | 15-60 Days |

| Transport Package | Wooden Case |

| Specification | International |

| Trademark | REMO |

| Origin | Taizhou China |

| HS Code | 8480719090 |

Product Description

Plastic Crash Helmet Injection Mould:1. High quality material

3. Hot Runner: DME/LKM/HASCO

4. Mould Life: 500, 000~1, 200, 000 Shot

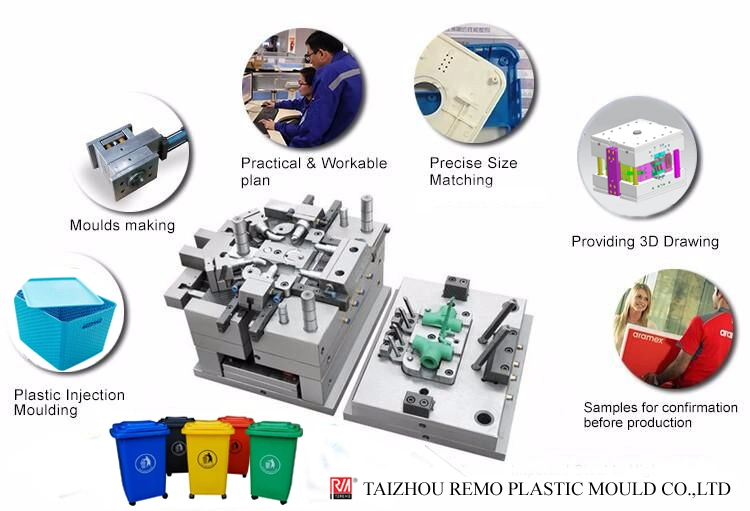

As a professional plastic mould manufacturer in China, we specialize in designing and making injection moulds for various plastic products. Our mould quotation will be made in 1 day and sent to consumers for reference. Quantity of mould and delivery time will be guaranteed.

Plastic Crash Helmet Injection Mould could be designed and manufacured as soon as the contract signed.

| Name | Description | ||||

| Mould Material | 45#, 50#, P20, H13, 718, 2738, NAk80, S136, SKd61 etc | ||||

| Mould Base | LKM, HASCO ect. | ||||

| Cavity | Single/multi | ||||

| Runner | Hot/cold | ||||

| Mould Design | 3D/2D Drawing | ||||

| Design Days | 3 days | ||||

| Design Software | UG, PROE, CAD, CAE, CAM, CAXA ect | ||||

| Plastic Material | PP, PC, PS, PE, PU, PVC, ABS, PMMA ect | ||||

| Mo uld Life | 300, 000-3, 000, 000 shots | ||||

| Injection System | Pin-point-gate | ||||

| Polish System | Mirror Polish | ||||

| P ayment | 40% of Deposit by T/T, 60% of Balance by T/T | ||||

| Delivery Time | 15-60days | ||||

| Specification | Depends on customers' requirements | ||||

Specification depends on customers requirements.

| Business Steps | |

| 1. R& D | We support customers' R& D. We'll make the files or improve the design if you need |

| 2. Quotation Making | Mould Quotation will be finished in 1 day according to information we get. |

| 3. Negotiation | The quality, price, material, delivery time, payment item, ect. |

| 4. Mould Design | 3-5 days for mould and product 3D/2D drawing design |

| 5. Mould | We will build the mould based on customers' requirements. Before making the mould, we'll send mould design to customers' approval first. Mould will be usually finished in 25-60 days |

| 6. Mould Testing | When moulds are finished, we will test the moulds to check if it will satisfy consumers' needs. And we will send samples for consumers' reference. |

| 7. Sample shoot | If the first sample come out is not satisfied by customers, we will modify the mould until it can meet customers' needs. |

| 8. Delivery | Delivery goods by sea or by air, according to customers' requirements. |

Our advantages:

1: Excellent Cooling System with extended cooling pipe

2: Copper Cooling for better cooling effects

3: Pre-opening system to improve cycle time

4: Semi-Hot Runner System to save clients cost on moulds

5: Mould Available for recycle Material

6: Excellent control of polish system

7: Weekly report with mould processing photos available

8: Samples and each trial out video available

9: Punctual sample time and delivery time

10: Logistic service available

11: Engineers available in client's factory for training

12: High quality mould with reasonable price

FOR MORE DETAILS,WELCOME TO SEND ME AN INQUIRY.