High Quality 718 Steel High Polishing Coat Clothese Trousers Shoes Plastic Hanger Mould

Basic Info

| Model NO. | Hanger Mould |

| Warranty | One Year |

| Shaping Mode | Injection Mould |

| Surface Finish Process | Polishing |

| Mould Cavity | Single Cavity |

| Plastic Material | PC |

| Process Combination Type | Single-Process Mode |

| Application | Furniture, Commodity |

| Runner | Cold Runner |

| Design Software | UG |

| Installation | Fixed |

| Certification | ISO |

| Standard | DME |

| Customized | Customized |

| After-sales Service | One Year |

| Transport Package | Wooden Case |

| Specification | P20 |

| Trademark | Mold |

| Origin | Huangyan, Taizhou, China |

| HS Code | 848071 |

| Production Capacity | 600 Sets |

Product Description

Product Description

Below is the general information and policy for our OEM/ODM plastic injection mold:

| Detailed info for mould steel | ||

| Mould material | Hardness | Mould life |

| P20 | HRC 28-33 | >300,000 shots |

| 718 | HRC 33-36 | >500,000 shots |

| H13 | HRC >43 | >800,000 shots |

| 2344 | HRC >48 | >800,000 shots |

| S136 | HRC 48-52 | >1,000,000 shots |

Lead Time :

| Quantity(Sets) | 1 - 1 | >1 |

| Est. Time(day) | 45 | To be negotiated |

| Jusheng Plastic Injection Mould | |

| Mould material | 45#, P20, H13, 718, 2738, NAK80, S136, CENA-1 etc. |

| Mould base | LKM, HASCO etc. |

| Standard Component | DME, HASCO, JIS etc. |

| Cavity | single/multi |

| Runner | hot/cold |

| Mould life | 50,0000-5,000,000shots |

| Design software | UG, PROE, CAD, SolidWorks etc. |

| Plastic material | PP, PC, PE, PS, PU, ABS, PVC, PA, POM, PMMA, PET, PPR etc. |

| Delivery time | 45--60days |

| Package | Wooden Case |

| Delivery | By Sea |

| Specifications | Depends on customer's requirements |

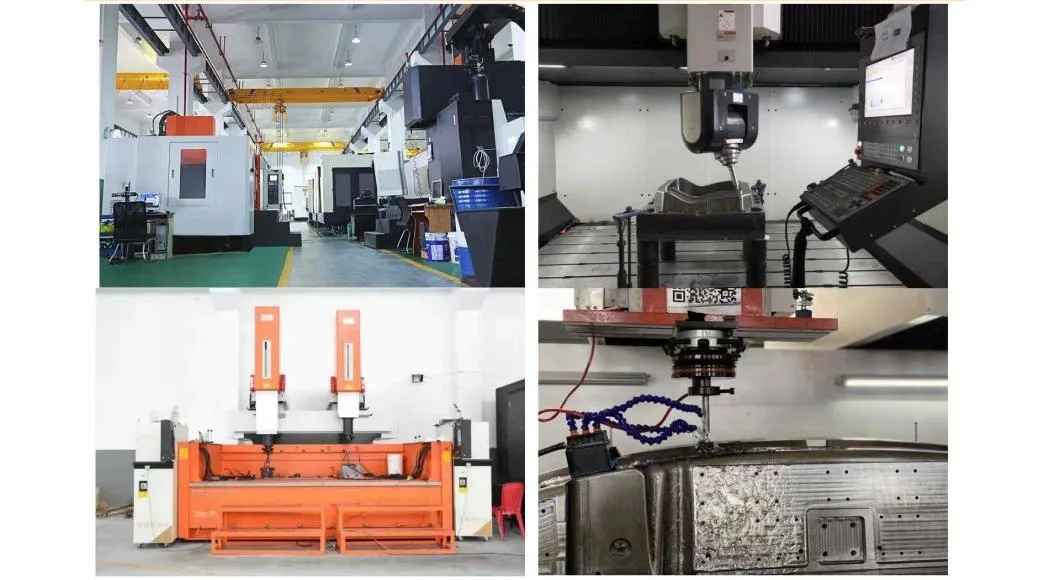

| Process Machine | CNC, High Speed Carve, EDM, Wire Cut, Driller, Grinder, fly cutter etc. |

Jusheng Mould Trade Process:

| 1. Quote | According to sample, drawing and specific requirement. |

| 2. Discussion | Mold material, cavity number, price, runner, payment, etc. |

| 3. S/C Signature | Approval for all the items |

| 4. Advance | Pay 50% by T/T |

| 5. Product Design Checking | We check the product design. If some position is not perfect, or can not be done on the mould, we will send customer the report. |

| 6. Mould Design | We make mould design on the basis of confirmed product design, and send to customer for confirmation. |

| 7. Mold Tooling | We start to make mold after mold design confirmed |

| 8. Mold Processing | Send report to customer once each week |

| 9. Mold Testing | Send trial samples and try-out report to customer for confirmation |

| 10. Mold Modification | According to customer's feedback |

| 11. Balance settlement | 50% by T/T after the customer approved the trial sample and mould quality. |

| 12. Delivery | Delivery by sea or air. The forwarder can be designated by your side. |

Company Information

Taizhou Jusheng Mould & Plastic Co.Ltd is a professional plastic injection mould maker and custom plastic parts manufacturer in mould city, Huangyan, Taizhou, Zhejiang, China.

We can make all kinds of plastic injection mould including daily use mould, auto part and motor part mould, home appliance mould, automotive mould, and industrial product mould.

We have rich experience in making customized plastic injection mould. Send me the inquiry with drawing and requirement (steel raw material, cavity no. etc) for mould, and I will reply you within 24 hours and quote for you within 2 working days.

You will know more about us if you visit our website: jushengmould.en.made-in-china.com

Why Choose Us?

| 1 | Best design,competitive price |

| 2 | 10 years' Rich experience worker |

| 3 | Professional in design & making plastic mould |

| 4 | One stop solution |

| 5 | On time delivery |

| 6 | Best after-sale service |

| 7 | Specialized in all kinds of plastic injection moulds |

Our Services

We Can Offer You:

1.Good steel with high hardness

2.Good accessories with high brightness

3.Good machining with high precise

4.In-time response on email, telephone calls or fax

5.In-time supply the quotation and mould designs

6.In-time commnication on the technical points

7.In-time sending pictures for the mould machining progress and mould finishing schedule

8.In-time mould test and sample delivery

9.In-time mould delivery

Sale Services

Pre-sale service:

Our company provide good salesman for professional and promptly communication.

In-sale service:

We have strong designer teams, will support customer R&D, If the customer send us samples, we can make product drawing and do the modification as per customer request and send to customer for approval. Also we will accord our experience and knowledge to provide customers our technological suggestions.

After-sale service:

If our product have quality problem during our guarantee period, we will send you free for replace the broken piece; also if you have any issue in using our moulds, we provide you professional communication.

Other Services

We make the commitment of service as below:

1.Lead time: 30-50 working days

2.Design period: 1-5 working days

3.Email reply: within 24 hours

4.Quotation: within 2 working days

5.Customer complaints: reply within 12 hours

6.Phone call service: 24H/7D/365D

7.Spare parts: 30%, 50%, 100%, according to specific requirement

8.Free sample: according to specific requirement

We guarantee to provide the best and quick mold service for customers!

Packaging & Shipping

Jusheng Mould Packing and Shipping:

Anti-rust oil is painted first, then plastic film, and finally wooden case.

Sent together with the mould:

a) Mould manual instruction

b) Engineering drawing in flash disk

c) One more set of mould spare parts: heater, ejector pin, bush, water nozzle, water pipe, hanging ring.

Our supplier:

FAQ

What We Need for Mould Quote?

1) Mould steel raw material you require or mould life your require

2) Mould cavity No. you want

3) 2D or 3D product drawing, or pictures with detailed size information(L*W*H, and thickness), or samples

4) Mould standard

5) Hot runner or cold runner, if hot runner, tell me brand of hot runner you require

6) Raw material of the product

7) Sample quantity and packing

For more detailed information, pls send inquiry now from below to us!